IGEABOND (Sumitomo Chemical)

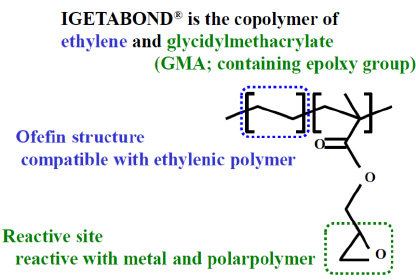

It is an ethylene copolymer that was developed by SUMITOMO CHEMICAL CO., LTD. And has an epoxy group which is the only reactant in the molecule.

IGETABOND has the following key features

- High reactivity of epoxy group

- Extremely low glass transition temperature

- High processability

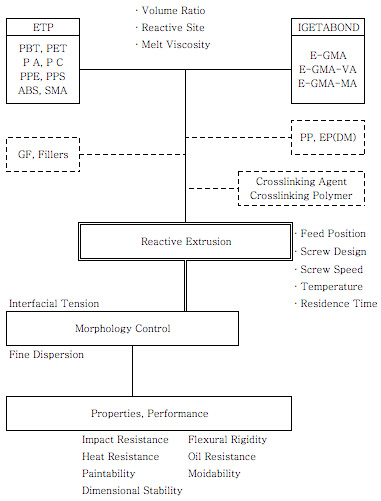

IGETABOND has been used to develop a variety of new Engineering Thermoplastics(hereinafter ETPs) and their alloys as a toughener and/or a compatibilizer. There are several grades of IGETABOND to meet a wide range of performance reqoirements.

GRADE

IGETABOND is a series of ethylene copolymers and terpolymers with glycidyl methacrylate(hereinafter GMA) as reactive sites.

| Polymer Type | E-GMA Copolymer | E-GMA-VA Terpolymer |

E-GMA-MA Terpolymer |

||||||

|---|---|---|---|---|---|---|---|---|---|

| Item | Test Method | Unit | BF-2C | BF-E | CG5001 | BF-2B | BF-7B | BF-7L | BF-7M |

| Glycidyl Methacry late(GMA) Cont. |

Sumitomo - Method |

wt% | 6 | 12 | 19 | 12 | 12 | 3 | 6 |

| Vinyl Acetate(VA) Cont. |

Sumitomo - Method |

wt% | - | - | - | 5 | 5 | - | - |

| Methyl Acrylate (MA) Cont. |

Sumitomo - Method |

wt% | - | - | - | - | - | 27 | 27 |

| MFR(190℃) | JIS k7210*1 | g/10min | 3 | 3 | 380 | 3 | 7 | 7 | 7 |

| Density | JIS K7112 | kg/㎥ | 930 | 940 | 950 | 950 | 950 | 960 | 960 |

| Tensile Strenght at Break | ASTM D638*2 | MPa | 18 | 19 | 4 | 19 | 17 | 4 | 3 |

| Elongation at Break |

ASTM D638*2 | % | 650 | 700 | 250 | 750 | 750 | 850 | 1000 |

| Apparent Bending Modulus | ASTM D747 | MPa | 98 | 69 | 3 | 39 | 39 | 6 | 4 |

| Surface Hardness | JIS K7215 | Shore D | 46 | 43 | 34 | 39 | 36 | 18 | 13 |

| Vicat Softening Point |

JIS K7206 | ℃ | 83 | 75 | <-30 | 68 | 66 | <25 | <25 |

| Brittle Point | JIS K7216 | ℃ | <-70 | <-70 | - | <-70 | <-70 | <-70 | <-70 |

| Melting Point | Sumitomo- Method(DSC) |

℃ | 105 | 103 | 88 | 95 | 95 | 60 | 52 |

| Glass Transition Temperature(Tg) |

Sumitomo- Method(DSC) |

℃ | -26 | -26 | -27 | -28 | -28 | -33 | -33 |

| Moisture Absorption |

JIS K6911 | % | <0.01 | <0.01 | - | <0.02 | <0.02 | <0.05 | <0.05 |

| Characteristic | High modulus High reactivity |

High reactivity |

High reactivity High flow |

High reactivity Strong adhesive |

Good impact strength at low temperature |

||||

| Main Application | Automotive parts / Electrical and electronic parts / Building material parts

Cable / Recycle PET modifier / Film etc. |

||||||||

Characteristics

IGETABOND can be characterized by the following properties.

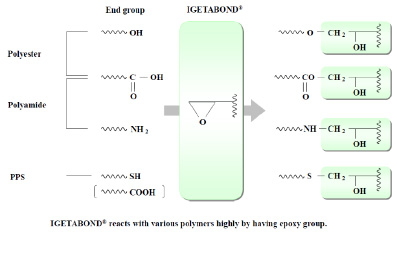

- High reactivity to various compounds or polymers with functional groups

- Elasticity and ductility

* Glass transition temperature(Tg) : Tg -25

* Tensile strength(TS) : TS 130kg/cm2

* Elongation(E) : E 500%

* Stiffness modulus : 400~1000kg/cm2

- High processability in extrusion or injection molding.

* Pellet Type

* Melting poinr : 50~105

* MFR : 2~30g/10min

Applications

Electronic Control Unit

Power Module

Alternator

Ignition coil

Lamp Reflector

Motor Brush Holder