XYRON (Asahi Kasei)

Production and sales began in March 1979. Grades include PPE/PS alloys, PPE/PA alloys, and PPE/PP alloys.

- Features: Excellent heat resistance, flame retardance, dimensional stability, and mechanical properties.

- Application fields: Automotive parts, electrical & electronic parts, industrial parts.

- High-performance grade example: L series - with greatly improved flowability and exceptionally low gas evolution.

- Capacity: 83,000 tons/year (35,000 tons/year in Japan, 48,000 tons/year in Singapore).

Classification for XYRON GRADES

| Type | GRADE | Characteristic | Main application | ||

|---|---|---|---|---|---|

| Polymers | Filler | ||||

| PPE | PS | - | 100V, 100Z, 220V, 220Z | Flammability, mold ability, Recycles | OA, electric Products Housing |

| 300H, 500H, 300V, 500V, 300Z, 500Z |

Electrical properites, Flammability, Heat stabilities |

Electrical and Electronic Case |

|||

| 1000H, SZ800 | High DTUL (150℃ ~ 170℃) | Electrical, Electronic Case, Trays | |||

| X0715, X5516, X0718, X0708, X0722, X0700, X9653 |

Heat stability (110℃ ~ 128℃) Impact strength |

Interior & Exterior for Automotive |

|||

| GF | G701H, G702H, G703H | Hot Water Stability GF10~30% Reinforced | Water Line Components | ||

| G701V, G702V, G703V | Electrical, Flammability Stiffness, Heat stability |

Electrical and Electronic parts |

|||

| SPECIAL MF | X1511, X1711, X334V, X334Z, X534V, X534Z |

Dimension stability Stiffness, Flammability, Low Density | Precision case | ||

| MF | X332V, X332Z, X333V, X333Z, X532V, X532Z, X533V, X533V |

Low-Warp Dimensional stability Stiffness, Flammability, Low Density |

OA Equipment Chassis | ||

| CF | X8400, X8600 | Electrically Conductive; High Stiffness, Flammability |

Chassis parts | ||

| PA | - | X5402, X5403, A1400 | Oil resistance Dimensional stability Electrical properites, |

Electrical and Electronic, Chassis |

|

| X9803, A0100, A0501, A0210 | Heat Resistance, High impact, Oil resistance | Interior & Exterior for Automotive |

|||

| AT600, AT610 | Good Flow; High Heat Resistance | Exterior(Auto) | |||

| GF | G010H, G010Z, G020H, G020Z | Oil resistance, High Stiffness, Dimensional stability Electrical properites |

Electrical and Electronic, Chassis |

||

| AG511, AG512, AG211, AG213 | Heat Resistance (200℃), Oil resistance Dimensional stability Stiffness |

Interior & Exterior for Automotive |

|||

| PO | - | FL50V, FT31V | Flammability, Sliding | Sliding parts | |

Classification by Heat Resistance & Flammability

Non Reinforced Grades

| ASTM DTUL (°C) 1.82 MPa |

ISO DTUL (°C) 1.80 MPa |

Flammability (UL94) | |||

|---|---|---|---|---|---|

| HB | V-1 | V-2 | V-0 | ||

| 76 | 70 | 1950J, 1951J | |||

| 85 | 78 | - | 100V | - | 100Z |

| 90 | 83 | 200H | 240V | 240W | 240Z |

| 100 | 94 | 300H | 340V | 340W | 340Z |

| 110 | 104 | 400H | - | - | 440Z |

| 106 | - | - | - | PV40Z | |

| 120 | 114 | 500H | 540V | - | 540Z |

| 130 | 124 | 600H | 640V | - | 640Z |

| 140 | 129 | - | - | - | 644Z |

| 134 | - | 740V | - | - | |

| 150 | 144 | - | - | - | SZ800 |

| 170 | 164 | 1000H(Eq.to HB) | - | - | - |

* Equivalent to UL94

| DTUL (°C)1.80 MPa ISO Method | Flammability (UL94) |

|---|---|

| HB | |

| 80 | A0210 |

| 113 | AT610 |

| 143 | AT600 |

| DTUL (°C)1.80 MPa ISO Method | Flammability (UL94) |

|---|---|

| V-1 | |

| 240 | DG235 |

| 241 | DG141 |

| 262 | DV166 |

| DTUL (°C)1.80 MPa ISO Method | Flammability (UL94) |

|---|---|

| HB | |

| 90(97) | EV103 |

| 120(135) | To702 |

Xyron™ application examples

AC adapter cases [ XYRON 340Z ]

Flyback transformers [ XYRON 540Z ]

Connector jacks [ XYRON 220V ]

Reinforced Grades

| ASTM DTUL |

ISO DTUL |

Flammability | Glass Fiber |

High-Stiffness Low-Warp High-Flow |

High-Stiffness Low-Warp |

High-Stiffness Ultralow-Warp |

Good Appearance Low-Warp |

Electro conductive |

Acoustic Damping |

|---|---|---|---|---|---|---|---|---|---|

| 97 | 100 | HB | X352H | ||||||

| V-1 | X331V X332V |

X1509 X1508 |

X351V X352V |

VN30V VT31V |

|||||

| V-0 | X1561 | ||||||||

| 110 | 108 | HB | X444H | X304H X404H |

|||||

| V-1 | |||||||||

| V-0 | X1712 | ||||||||

| 120 | 118 | HB | X552H | ||||||

| V-1 | L542V L543V X1744 L544V L554V L564V L565V |

X531V | L524V | X551V X552V |

X8610 | ||||

| V-0 | L542Z L543Z L564Z L574Z |

X531Z | X8401 | ||||||

| 130 | 128 | HB | G701H | X604H | |||||

| V-1 | G701V | X603V | |||||||

| 130 | 133 | V-1 | L654V | ||||||

| 140 | 139 | HB | G702H G703H |

||||||

| V-1 | G702V G703V |

| DTUL (°C)1.80 MPa ISO Method | Flammability(UL-94) |

|---|---|

| HB | |

| 138 | AT602 |

| 150 | AG511 |

| 180 | AG512 |

| 199 | AG211 |

| 266 | AG213 |

| DTUL (°C)1.80 MPa ISO Method(ASTM Method) | Flammability(UL-94) |

|---|---|

| HB | |

| 100(120) | TT520(HB) |

| 120(135) |

* Equivalent to UL94

examples

CD-ROM drive trays [ XYRON X1519 ]

CD drive chassis [ XYRON X332V ]

Laser printer frame chassis [ UNSPECIFIED ]

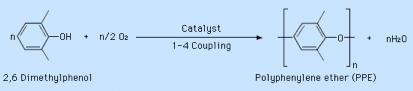

PPE Base Resin

Characteristics

- Noncrystalline polymer

- High heat resistance (Tg: 214 ℃ by DSC)

- Low specific gravity (1.06 )

- Good electrical properties (Dielectric constant: 2.45 at 1 MHz, Dielectric loss: 0.0007 at 1 MHz)

- Flame retardant

- Dissolves well in aromatic hydrocarbons (Toluene, Xylene, etc.) and halogenated hydrocarbons (Chloroform, etc.)

| GRADE | Test method | ||

|---|---|---|---|

| Standard (S201A) | Low viscosity(S202A) | ||

| Reduced viscosity | 0.52 | 0.41 | 0.5g/dl-PPE in CHCl3, 30 ℃ |

| Molecular weight (Mn) | Ca 19,000 | Ca 16,000 | GPC calibrated with polystyrene |

| Appearance | White powder | White powder | |

Applications

Base resin for polymer alloys.

Fuel cell for Xyron Grades

| Parts | Picture | Current | Xyron Grade | Key Point |

|---|---|---|---|---|

| Water tank, Ion Exchange, Resin case |  |

PP | 500H | Low Ionic elution Water resistance Heat resistance |

|

||||

| Pipe |  |

PPS (Z230) | WG731 X1763 |

Cost down ( water goes pipe ) Low Ionic elution |

| Stack Manifold |  |

PPS/GF | X1763 | Cost down Low Ionic elution |

| Stack Frame |  |

PPS/GF | 500H | Low Ionic elution Water resistance Heat resistance |

XYRON Li-Ion cell

| Property | PP/PPE type Alloy |

PA/PPE type Alloy |

PPE/PS type Alloy |

PBT Flame resisting Grade non-filler |

PP Flame resisting Grade Non-filler |

||

|---|---|---|---|---|---|---|---|

| Xyron™ TF700 (developed) |

Xyron™ AF700 | Xyron™ 340Z | |||||

| Specific Gravity | ISO1183 | 1.07 | 1.09 | 1.08 | 1.32 | 1.02 | |

| Tensile Strength | MPa | ISO527 | 53 | 58 | 54 | 50 | 18 |

| Tensile Elongation |

% | ISO527 | 12 | 32 | 13 | 10 | 84 |

| Flexural Strength | MPa | ISO178 | 77 | 93 | 88 | 80 | 39 |

| Flexural Modulus | MPa | ISO178 | 2270 | 2400 | 2400 | 2800 | 1680 |

| Charpy Impact Strength (notched) |

KJ/㎡ | ISO179 | 7 | 8 | 15 | 3 | 6 |

| Relative Thermal Index | ℃ | ISO75,1.8MPa | 109 | 98 | 94 | 80 | 60 |

| ISO75,0.45MPa | 122 | 192 | 110 | 160 | 102 | ||

| Flammability | UL94 | V-0 (1.6mm) V-1 (0.8mm) |

V-0(1.6mm) | V-0(1.6mm, 0.8mm) |

V-0 | V-0(1.5mm) V-2(0.5mm) |

|

| Mold Shrinkage | % | Flowing direction |

0.8 | 1.5 | 0.5 | - | 1.6 |

| Right angle direction |

1.2 | 2.0 | 0.8 | - | 1.4 | ||

| Flatness | Mn | ASAHI KASEI method |

0.92 | 0.30 | 0.12 | - | - |

| breakdown voltage(UL746A) |

kV / MM | Dry | 36 | 25 | 29 | 18 | 33 |

| Tracking | V | IEC-60112∙2003 | >600상당 | >600 | 225 | 175-250 | >600 |

| ATF OIL | - | ASAHI KASEI method |

NO fracture | NO fracture | fracture | - | - |

| characteristics | Oil resistance, Electrolyte, electric insulation |

Heat resistance, Thermal stiffness |

Dimension, Acid resistance, Alkali resistance |

- | - | ||

| Property | PP/PPE type Alloy | PPE/PS type Alloy | PBT Grade GF30% |

|||

|---|---|---|---|---|---|---|

| Xyron™ TA720 (developed) |

Xyron™ L543Z | Xyron™ X532Z | ||||

| Specific Gravity | ISO1183 | 1.21 | 1.32 | 1.22 | 1.57 | |

| Tensile Strength |

MPa | ISO527 | 43 | 80 | 88 | 100 |

| Tensile Elongation |

% | ISO527 | 4 | 2 | 3 | 3 |

| Flexural Strength | MPa | ISO178 | 78 | 138 | 135 | 156 |

| Flexural Modulus | MPa | ISO178 | 3700 | 7060 | 6200 | 9900 |

| Charpy Impact Strength(notched) |

KJ/㎡ | ISO179 | 5 | 5 | 6 | 9 |

| Relative Thermal Index |

℃ | ISO75,1.8MPa | 110 | 118 | 130 | 200 |

| ISO75,0.45MPa | 125 | - | - | - | ||

| Flammability | UL94 1.6mmt | V-0 (1.6mm) | V-0(1.6mm) V-1(0.8mm) |

V-0(1.6mm,0.8mm) | V-0(1.5mm) | |

| Mold Shrinkage | % | Flowing direction |

0.7 | 0.2 | 0.3 | 0.3 |

| Right angle direction |

0.9 | 0.5 | 0.5 | 1.4 | ||

| Flatness | Mn | ASAHI KASEI method |

0.59 | 0.34 | 0.72 | 4.8 |

| breakdown voltage (UL746A) |

kV / MM | Dry | - | - | - | 24 |

| Tracking | V | IEC-60112∙2003 | >600 | - | - | - |

| ATF OIL | - | ASAHI KASEI methods |

NO fracture | NO fracture | fracture | - |

| feature | Oil resistance, Electrolyte, electric insulation |

Dimension, Acid resistance, Alkali resistance |

- | |||

Application

- Case/Holder: XYRON L543Z,X532Z

- Spacer/Insulating board: XYRON 340Z

Case/Holder [ XYRON L543Z, X532Z ]

Solar cell (junction box & connecter)

Product physical properties

| Characteristic | Unit | Test method | Test condition | 540Z | 644Z | PV40Z | |

|---|---|---|---|---|---|---|---|

| Specific Gravity | ISO1183 | 23℃ | 1.08 | 1.09 | - | ||

| moisture absorption | % | ISO62 | Immersion for 24Hr |

0.10 | 0.10 | - | |

Thermal |

DTUL Relative Thermal Index | ℃ | ISO75-1 | 1.80MPa | 114 | 129 | 106 |

| ASTM D648 | 1.80MPa | 120 | - | - | |||

| coefficient of linear expansion |

mm/ mm/ ℃ |

ISO11359 | -30℃-65℃ | 7.0 x 10-5 | 7.0 x 10-5 | - | |

| Percentage of contraction | % | ASTM D648 | 1.82MPa | 120 | - | - | |

Machinery |

Tensile Strength | MPa | ISO527 | 23℃ 50% RH | 60 | 74 | 56 |

| Tensile yielding | % | ISO527 | 23℃ 50% RH | 13 | 9 | 18 | |

| Flexural Strength | MPa | ISO178 | 23℃ 50% RH | 98 | 110 | 88 | |

| Flexural Modulus | MPa | ISO178 | 23℃ 50% RH | 2430 | 2440 | 2060 | |

| Charpy Impact strength | KJ/㎡ | ISO179 | 4mm Notched |

15 | 21 | 46 | |

Electronic |

Flammability | UL94 | Black | 0.66mm V-0 1.5mm 5VB 2.5MM 5VA |

0.75mmV-0 2.0mm5VA | 0.75mmV-0 2.0mm5VB 2.5mm5VA | |

| CTI | UL PLC rank | 0 | 2 | 0 | |||

| RTI | ℃ | Elec/Imp/Str(1.5mm) | 110/105/110 | 125/125/125 | 105/105/105 | ||

| HWI | UL PLC rank | 0(1.5mm) | 2(1.0mm) | 1(0.75mm) | |||

| HAI | UL PLC rank | 0(1.5mm) | 0(1.0mm) | 2(0.75mm) | |||

| HVTR | UL PLC rank | 2 | 4 | - | |||

| Weather Resistance | UL746C | Black | f1 0.75mm V-0 2.5mm 5VA | f1 1.0mm V-0 2.0mm 5VA | f1 0.75mm V-0 2.5mm 5VA | ||

Mold |

Resins Temperature | ℃ | 240-290 | 280-320 | 280-320 | ||

| Metallic mold Temperature | ℃ | 50-80 | 60-100 | 50-90 | |||

| Reserved Dry temperature | ℃ | 90-100 | 90-100 | 90-110 | |||

| Reserved Dry time | ℃ | 2-4 | 2-4 | 2-4 | |||

XYRON application example

Solar power panel

connector and J/B [ 540Z, 640Z, 644Z ]