PHENOLIC MOLDING COMPOUNDS (Panasonic)

Phenol-formaldehyde resins, as a group, are formed by a step-growth polymerization reaction that can be either acid- or base-catalyzed. Hexamethylenetetramine or "hexamine" is a hardener added to crosslink novolac. Base-catalyzed phenol-formaldehyde resins are made with a formaldehyde to phenol ratio of greater than one, these resins are called resoles. PHENOL resin in pulp, wood flour such as fillers, coloring agents, denaturing agents are added to make the PHENOL MOLDING COMPOUND.

| GRADE | APPLICATION | CHARATERISTICS | MOLDING CONDITION |

|---|---|---|---|

| CN4404 | Automotive parts(small), Home appliance, OA, AV | Good for Plastic machinability (small size commutator) |

Transfer, Compression |

| CN6442 | Automotive parts(starter), Power tool Vacuum cleaner |

Heat resistance (swirling strength), Ammonia free |

Transfer, Compression |

| CN6548 | Automotive parts (DC Motor B/H) | Heat resistance, dimensional stability | Injection , Compression |

| CN6556 | Automotive parts(starter, wiper), Power tool Vacuum cleaner |

Heat resistance (swirling strength) | Transfer, Compression |

| CN6575 | Automotive parts(starter, wiper), Power tool Vacuum cleaner |

Dimensional stability | Transfer, Compression |

| CN6590 | Automotive parts(starter/small commutator) | Good for Plastic machinability, Elongates in shaft insertion |

Transfer, Compression |

| CN6621 | Automotive parts(fuel pump) | Fuel resistance | Transfer, Compression |

| CN6641 | Automotive parts(small, stator), Home appliance |

Good for Plastic machinability (small commutator) |

Transfer, Compression |

| CN6741 | Home appliance, Power tool, Automotive parts(small, stator) |

Elongates in shaft insertion Heat and moisture resistance |

Transfer, Compression |

| CN6771 | Automotive parts(starter, wiper), Power tool Vacuum cleaner |

Heat and moisture resistance (Excellent dimensional stability) |

Transfer, Compression |

| CN6776 | Automotive parts(commutator), Vacuum cleaner | Heat resistance, Dimensional change is low | Injection , Compression |

| CN6853 | Automotive parts(commutator), Vacuum cleaner | Heat resistance, Dimensional change is low | Transfer, Compression |

| CN6957 | Fuel pump commutator | Fuel resistance | Transfer, Compression |

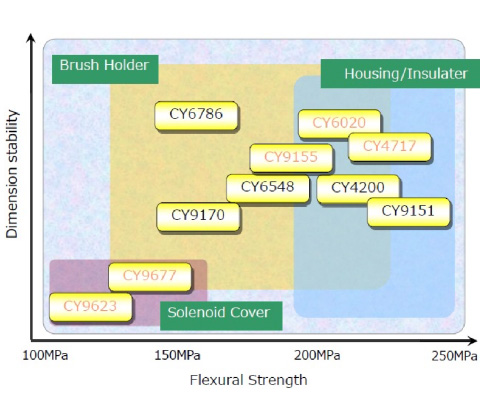

| CY4200 | Housing/Insulator, PWI, Master cylinder piston, Pulley |

Heat resistance | Injection , Compression |

| CY4713 | Automotive parts(engine parts) | Heat resistance strength, dimensional stability chemical resistance |

Injection |

| CY4717 | Automotive parts(starter), Vacuum cleaner, Vacuum cleaner |

Heat resistance , Dimensional change is low | Injection , Compression |

| CY6456 | Automotive parts(fuel pump impeller, pulley) | Excellent dimensional stability, Fuel resistance |

Transfer, Compression |

| CY6548 | Fuel pump impeller housing, Diesel rotor case | Excellent dimensional stability, Fuel resistance |

Injection |

| CY6786 | Fuel pump impeller housing, Diesel rotor case, PWI |

Excellent dimensional stability | Injection |

| CY8611 | Automotive parts(ignition switch) | Ammonia free | Injection |

| CY9177 | Master cylinder piston | Dimensional stability | Injection |

| CYD100 | PWI | Dimensional stability, Heat resistance | Injection , Compression |

BY APPLICATION CHARACTERISTICS

1. Automotive

Applications : Commutator, Pulley, Stator, Gear, Brush holder, Master cylinder Piston, PWI(Pad Wear Indicator), Fuel pump impeller case, Insulator(Insulation)

Commutator

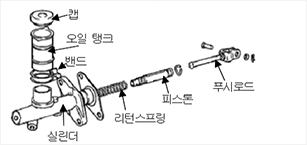

Master Cylinder Piston

Master Cylinder Piston

Housing (Power window, sunroof)

Brush Holder (Blower motor, EPS motor, Starter motor, Fan motor)

Insulation Bush/

Terminal (Starter motor, Alternator)

Solenoid Cover

* Master cylinder Piston

| Conventional | Recommend | ||||

|---|---|---|---|---|---|

| Insulations resistance | Normal | JIS K6911 | Ω | 1010 ~ 1013 | 1010 ~ 1013 |

| After boiling | JIS K6911 | Ω | 109 ~ 1011 | 109 ~ 1011 | |

| Flexural strength | JIS K6911 | MPa | 125 ~ 155 | 180 ~ 220 | |

| Flexural modulus | JIS K6911 | GPa | 11.0 ~ 17.0 | 14.0 ~ 20.0 | |

| Tensile strength | JIS K6911 | MPa | 40 ~ 70 | 80 ~ 110 | |

| Compression strength | JIS K6911 | MPa | 170 ~ 210 | 220 ~ 260 | |

| Charpy impact strength | JIS K6911 | kJ/m2 | 2.5 ~ 4.5 | 4.5 ~ 6.5 | |

| Molding shrinkage | JIS K6911 | % | 0.35 ~ 0.55 | 0.35 ~ 0.55 | |

| Heat distortion temperature(HDT) |

JIS K6911 | ℃ | 185 < | 185 < | |

| Water absorption | JIS K6911 | % | 0.1 > | 0.1 > | |

| Specific gravity | JIS K6911 | 1.75 ~ 1.85 | 1.75 ~ 1.85 | ||

| Resin type | - | - | Novolac | Novolac | |

| Actual used | - | - | |||

2. Electrical and electronic products

Applications : For coil bobbin, Breaker, Commutator for vacuum, DC motor commutator

* Commutator for vacuum

| Recommend 1 | Recommend 2 | |||

|---|---|---|---|---|

| Flexural strength | ISO 178 | MPa | 170 ~ 220 | 240 ~ 290 |

| Flexural modulus | ISO 178 | GPa | 19.0 ~ 24.0 | 19.0 ~ 22.0 |

| Tensile strength | ISO 527 | MPa | 70 ~ 100 | 120 ~ 160 |

| Tensile modulus | ISO 527 | GPa | 14.0 ~ 18.0 | 15.0 ~ 20.0 |

| Compression strength | ISO 604 | MPa | 180 ~ 230 | 280 ~ 330 |

| Charpy impact strength | ISO 179 | kJ/m2 | > 10.0 | > 14.0 |

| Charpy impact strength Notched | ISO 179 | kJ/m2 | > 2.5 | > 3.0 |

| Molding shrinkage | JIS K6911 | % | 0.20 ~ 0.40 | 0.30 ~ 0.50 |

| Water absorption | ISO 62 | % | < 0.25 | < 0.18 |

| Specific gravity | ISO 1183 | 1.85 ~ 1.95 | 1.77 ~ 1.87 | |

| Heat Deflection Temperature A at; 1.8MPa(after baking) |

ISO 75 | ℃ | >250 | >250 |

| Heat Deflection Temperature A at; 8.0MPa(after baking) |

ISO 75 | ℃ | >170 | >175 |

| Color | - | - | Black | Black |

| Resin type | - | - | Novolac | Resol |

3. Dish , Commodity

Applications : For table ware and others