DELPET (Asahi Kasei)

Asahi Kasei acrylic resin(PMMA) DELPET™ has an exellent transparency , surface hardness and weatherability. Main applications of DELPET™ are outer/inner parts for automobile , optical goods , industrial and general parts/goods. We also have High-performance grade such as highly heat resistant PMMA grades and BIMODAL grades.

DELPET Grade Line up

| Grade | |

|---|---|

| Standard Grades | 720V, 70FR, 560F, 70NH, 60N, 80NH, 80N, 80NR, 80NR-S, 80HD, LP-1, 80NB |

| Bimodal Grades | 80NE, 80EB |

| Special Grades for Light Guiding Plates | 70FR, 70NH, 80NH |

| Heat-resistant Grades | 980N, 981J, 982J, PM120N, PM130N |

| High Impact Grades | SR6200, SR6350, SR6500, SR8200, SR8350, SR8500, SRB100, SRG095, SRG097, SRB215, SRB235, SRE255, SRJ259 |

| Filter Grades | FILA72, FILA82, FILB72, FILB82 |

| PB Series (Piano Black) | PB01, PB21, PB22 |

About Bimodal

ASAHI KASEI CHEMICALS have developed brand-new PMMA which surpassed conventional PMMA by original technology.

- DELPET 80NE has superior high flow ability in injection molding.

① The flow distance is about 20% longer than that of 80N.

(It is equal to that of conventional PMMA which MFR is about 4g/10min..)

② Molding cycle time is expected to shorten for large-sized or thick-walled parts.

③ This resin makes possible to mold more complicated shape or thin-walled parts in

comparison with conventional PMMA.

- DELPET 80NE has the same mechanical strength, heat resistance and solvent resistance as 80N.

- DELPET 80NE has higher swelling ratio than conventional PMMA, so improvement of the jetting problem is expected.

* Swelling : Swelling of molten resin after the passage through a injection gate.

* Jetting :Flow of molten resin in contact with a mold surface deficiently, after the passage through a injection gate.

A line-shaped mark occurs in the vicinity of a gate.

- DELPET 80NE has high transparency, high gloss surface and other typical properties as the

same as conventional PMMA.

DELPET General purpose

| Classification | Evaluation method | Unit | 560F | 60N | 80N | LP-1 |

|---|---|---|---|---|---|---|

| Melting index | ISO 1133 cond13 | g/10min | 13.0 | 8.0 | 2.0 | 1.1 |

| Modulus of elasticity | ISO 527-2/ 1A/1 | MPa | 3200 | 3200 | 3300 | 3300 |

| Tensile stress | ISO 527-2/ 1A/5 | MPa | 69 | 72 | 75 | 75 |

| Charpy Sample impact force | ISO 179/1eA | KJ/㎡ | 1.3 | 1.3 | 1.4 | 1.4 |

| Load deviation temperature |

ISO 75-1 ISO 75-2 | °C | 84 | 91 | 100 | 97 |

| Vicat Softening temperature |

ISO 306 B 50 | °C | 94 | 98 | 109 | 104 |

| density | ISO 1183 | g/㎤ | 1.19 | 1.19 | 1.19 | 1.19 |

| Index of refraction | ISO 489 | - | 1.49 | 1.49 | 1.49 | 1.49 |

| Visual transmittance | ISO 13468-1 | % | 92 | 92 | 92 | 92 |

| Bending modulus | ISO 178 | MPa | 3200 | 3300 | 3300 | 3300 |

| Bending stress | ISO 178 | MPa | 120 | 120 | 130 | 130 |

| Rockwell Lightness | ISO 2039-2 | (M-Scale) | 92 | 95 | 100 | 95 |

| Mold dimension shrinking |

Asahi Method | cm/cm | 0.002-0.006 | 0.002-0.006 | 0.002-0.006 | 0.002-0.006 |

| Characteristics | High mobility. | Fluidly,The most standard Grade. | High thermal resistance. |

High resistance to organic crack solvents. |

||

| Application case | General | General | Standard | Extrusion sheet | ||

| POPL | - | - | - | - | ||

| UL | 94HB | 94HB | 94HB | 94HB | ||

| FDA | Match | Match | Match | Match | ||

DELPET Light guide panel

| Property | Test Method | Unit | 80NH | 70NHX | 70FH |

|---|---|---|---|---|---|

| Specific gravity | ASTM D 792 | - | 1.19 | 1.19 | 1.19 |

| Shrinkage from mold dimensions |

Asahi Method | cm/cm | 0.002-0.006 | 0.002-0.006 | 0.002-0.006 |

| Melt Flow Rate | ASTM D 1238 (230°C.3.8kg, CONDITION-I) |

g/10min | 5.5 | 6.5 | 13.0 |

| Total luminous transmittance |

ASTM D 1003 | % | 93 | 93 | 93 |

| Index of refraction | ASTM D 542 | - | 1.49 | 1.49 | 1.49 |

| Tensile Yield Strength | ASTM D 638 | MPa | 73 | 73 | 70 |

| Flexural strength | ASTM D 790 | MPa | 118 | 118 | 118 |

| Flexural modulus | ASTM D 790 | MPa | 3300 | 3300 | 3300 |

| Izod impact strength of notched specimens | ASTM D 256 | KJ/㎡ | 1.6 | 1.6 | 1.6 |

| Coefficient of linear thermal expansion |

ASTM D 696 | 10-5.cm / cm.°C |

6 | 6 | 6 |

| Vicat softening temperature |

ASTM D 1525 | °C | 120 | 114 | 107 |

| Features | Heat resistance, good flow ability, mold release. |

Good flow ability | Excellent flow ability, mold release. |

||

| Application examples | Optical purpose. Light-conducting plates. |

Optical purpose. Light-conducting plates. |

Optical purpose. Light-conducting plates. |

||

| POPL | - | - | - | ||

| UL | 94HB | 94HB | 94HB | ||

| FDA | - | - | - | ||

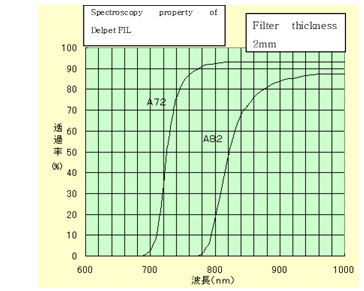

DELPET ®FIL(filter)

GRADED charateristics

DELPET FIL has the function of the filter itself

- Aspherical LENS, FILTER can be freely designed.

- The beautiful appearance of acrylic resin can be saved.

- Integrated molding with peripheral part is also possible and the

process is simplified.

Property of FILGrade

FIL Ais equivalent to60N、FIL Bis equivalent to80N.

Delpet ®SR Shock resistance

application

- Telephone button

- automobile side visor

DELPET 80NR(For Lens)

| TEST Method(ISO) | Unit | 80N | 80NR | 80NH | |

|---|---|---|---|---|---|

| Melt flow rate(230℃, 37, 3N) | 1133 cond | g/min | 2.0 | 2.1 | 5.5 |

| Spiral flow length | ASAHI KASEI METHOD |

Cm | 27 | 27 | 34 |

| DTUL(℃) After annealing | 75-1 75-2 |

℃ | 100 | 100 | 100 |

| VST(℃) | 306 B 50 | ℃ | 109 | 108 | 109 |

| Tensile modulus | 527-2/1A/1 | Mpa | 3300 | 3300 | 3330 |

| Tensile strength at break | 527-2/1A/5 | Mpa | 77 | 77 | 75 |

| Tensile strain at break | 527-2/1A/5 | Mpa | 6 | 6 | 5 |

| Charpy impact strength(unnotched) | 179/1eU | KJ/㎡ | 22 | 22 | 20 |

| Charpy impact strength(notched) | ASTM D256 | KJ/㎡ | 1.4 | 1.4 | 1.3 |

| Flammability | UL94 | - | HB | HB | HB |

| Visible particles | ASAHI Method |

Value | <1 | <1 | <1 |

Molding Condition

| Delpet 80N | Delpet 80NR | Delpet 80NH | |

|---|---|---|---|

| Pre-drying | 90℃, 2~6hr | 90℃, 2~5hr | 90℃, 2~5hr |

| Cylinder temp-nozzle | 220~260℃ | 220~260℃ | 210~250℃ |

| Cylinder temp-hopper | 220~240℃ | 20~240℃ | 210~230℃ |

| Injection pressure | 50~150MPa | ||

| Mold temperature | 50~90℃ | ||

| Annealing Temp | |||