CR > SKYPRENE

Skyprene polychloroprene rubbers are often specified by design engineers because of their superior properties, such as their resistance to cold, heat, abrasion, ozone, oil and chemicals.

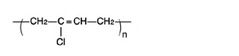

CHEMICAL FORMULA / DIAGRAM

Introduction of representative grade

| GRADE | TYPE | MOONEY VISCOSITY |

10% SOLUTION VISCOSITY |

CRISTALLIZATION | APPLICATION |

|---|---|---|---|---|---|

| B-5A | Mercaptan-modified | 40~50** | Very slow |

ELECTRICAL WIRE AND CABLES, AUTOMOTIVE RUBBER PART'S, HOSES AND BELT, ANTI VIBRATION, INDERSTRIL RUBBER GOODF |

|

| B-5 | 45~53** | Slow | |||

| B-10 | 447~55** | ||||

| B-31 | 36~44** | medium | |||

| B-30 | 45~53** | ||||

| Y-31 | 90~110** | ||||

| Y-30S | |||||

| Y-30SA | |||||

| Y-30H | |||||

| Y-30HA |

EXTRUDED PRODUCTS(HOSES,GASKETS), CALENDER PRODUCTS |

||||

| Y-20E | 43~53** | ||||

| P-90 | Xanthogen-mondified | 40~50** | Relatively fast |

ELECTRICAL WIRE and cable, calender products |

|

| E-20 | 43~53** | Slow |

EXTRUDED PRODUCTS(HOSES,GASKETS), CALENDER PRODUCTS |

||

| E-20H | 54~74** | ||||

| E-33 | 43~53** | Medium | |||

| R-10 | Sulfur-modified | 35~55 at the time of production | Slow |

belts, rolls, spongea (wet suits), rubber threads,linings |

|

| R-22 | 35~55 at the time of production | Medium | |||

| 505 | 34~54 at the time of production | Relatively fast | |||

| G-42 | Mercaptan-modified | 36~38* | 70~130 | fast | adhesive for high filling,genneral industrial product. |

| G-41H | 75~90* | 250~500 | |||

| G-40S | 81~95* | 300~600 | |||

| G-55 | 80~96* | 300~600 | |||

| G-40S-1 | 81~99* | ||||

| G40T | 96~113* | 300~900 | |||

| G-70 | 1600~2400 | ||||

| TSR-41 | 40~50** | Very slow | |||

| TSR-42 | 40~50** | Slow |

ELECTRICAL WIRE AND CABLES, AUTOMOTIVE RUBBER PART'S, HOSES AND BELT, ANTI VIBRATION rubber parts, coated fabrics, industrial rubber parts. |

||

| TSR-44 | 40~50** | Very slow | |||

| TSR-48 | 45~53** | Medium | |||

| TSR-51 | 55~75** | Very slow | |||

| TSR-52 | 55~75** | Slow | |||

| TSR-53 | 55~75** | Very slow | |||

| TSR-54 | 60~80** | ||||

| TSR-61 | 90~110** |

HEAT resistant grade

| GRADE | type | Mooney viscosity | 10% solution viscosity | Crystallization rate | Application |

|---|---|---|---|---|---|

| 510L | 35~47* | 80~170 | Fast | Adhesive for heat resistance |

|

| 570 | 42~64* | 100~280 | Medium | ||

| 580 | 35~47* | 60~150 | Very slow | ||

| 580H | 57~77* | 140~300 |

CR-LATEX

SKYPRENE LATEX GRADE 는 유성 접착제를 대체해서 개발되었습니다. TOSOH의 GFL series는 건조 접착에 사용되기 위해 디자인 되었고,GEL-FREE 구성과 높은 가곡성을 가진 ZnO, 일반적인 카르복실 클로로프렌 라덱스보다 뛰어난 성질을 가지고 있습니다.게다가 GFL series는 일반적인 음이온 라텍스보다 기계적 특성과 전기적 안정성이 나은 제품입니다.

| SKYPRENE | GFL-820 | GFL-890 | GFL-280 | SOLVEN TYPE | ||

|---|---|---|---|---|---|---|

| formulation | G-40S | 50 | ||||

| SKYPRENE LATEX | 100 | Y-30S | 50 | |||

| Terpene phenol | 20 | ZnO | 3 | |||

| Rosin ester | 20 | Phenolic | 20 | |||

| ZnO | 0.5 | MgO | 2 | |||

| thickener | 5.0 | solvent | 810 | |||

| Property at 250C | ||||||

| Viscosity | mPa*s | 5400 | 5300 | 5600 | 3200 | |

| Ph | 5.4 | 5.3 | 5.7 | - | ||

| Peel strength(convas/canvas) | ||||||

| after 1 hrs(230C) | N/25mm | 64 | 99 | 90 | 53 | |

| after 7 days(230C) | N/25mm | 65 | 100 | 114 | 150 | |

| after 7 days(800C) | N/25mm | 7 | 27 | 29 | 34 | |

| Water resistance(230C) | N/25mm | 45 | 56 | 75 | 143 | |

| Tack retention time | min | >120 | 70 | 40 | 60 | |

| 1) resin emulsion L 100(arakawa chamicals) | Test condition | |||||

| 2) resin emulsion E 720(arakawa chamicals) | Dry method : 800c for 5min | |||||

| 3) resin emulsion AZ-SW(osaki kogyo) | Press : 5.4kg/cm2for 20 sec | |||||

| 4) 10%UH-420(asahidenka kogyo) | Peel rate : 100mm/min | |||||

| 5) alkyl phenolic resin TD-773(dianippon & chemicals) | Water resistancr : aging(7 days), dipping(3days) | |||||

CR-LATEX GRADE:

| Grade | GFL-820 | GFL-890 | GFL-280 | LA-660 | SL-360 | LA-502 |

|---|---|---|---|---|---|---|

| Polymer type | Chloroprene/methcrylic acid | Rosin solt | Rosin solt | Rosin solt | ||

| Emulsifying agent | Anionic | |||||

| Solid content | 50-56 | 50-56 | 50-56 | 52-56 | 50-54 | 50-54 |

| Ph at 25deg.C | 2.1-6.0 | 2.1-6.0 | 2.1-6.0 | 12-14 | 12.5-13.5 | 12.5-13.5 |

| Specific gravity at 25deg.C | 1.12 | 1.12 | 1.12 | 1.10-1.14 | 1.12 | 1.124 |

| Gel content | None | None | None | Contain | Free | Contain |

| Molecular weight | Low | Low | Low | Gel | High | Gel |

| Crystallization rate | Medium | Medium | Fast | Medium | fast | Medium |

| Stability mechanical | Good | Good | Good | Good | good | Good |

| Electrolyte | Good | Good | Good | Good | Good | Good |

| Storage | good | good | good | good | good | good |

| freeze | unstable | unstable | unstable | unstable | unstable | unstable |