ASAFLEX - High-performance Clear StyrenicBlockCopolymers (SBC)

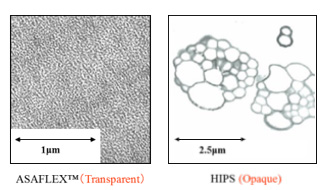

ASAFLEX is a styrene-butadiene block copolymer (SBC) characterized by both superior transparency and high impact resistance. As the polybutadiene-phase (i.e., the rubber-phase) dispersion in ASAFLEX is on a finer scale than the wavelength of visible light, ASAFLEX has flexibility and hinge characteristics while maintaining high transparency.

Due to good compatibility with styrenic resins such as GPPS, ASAFLEX can be blended at arbitrary ratio.

Futures

- High transparency and gloss

- Superior impact strength

- Superior compatibility with styrenic resins

- Excellent flexibility yielded to GPPS

- High hinge characteristics

- Broad range of processing methods and conditions (i.e., inflation molding)

- Stable to gamma-radiation sterilization

- Low double refraction like acrylate resin

- Coloring and printing capability

GRADE LINE UP

| Property | Test Method | Units | Injection | Sheet | |||

|---|---|---|---|---|---|---|---|

| 805 | 810 | 825 | 830 | 840 | |||

| 815 (With wax) |

835 (With wax) |

845 (With wax) |

|||||

| Density | ISO1183 | Kg/㎥ | 1.02×10³ | 1.01×10³ | 1.02×10³ | 1.01×10³ | 1.02×10³ |

| Water absorption | ISO62 | % | <0.1 | <0.1 | <0.1 | <0.1 | <0.1 |

| MFR(200℃) | ISO1133 | g./10min | 10 | 5 | 6 | 5 | 7 |

| Mold shrinkage | - | % | 0.2~0.8 | 0.2~0.8 | 0.2~0.8 | 0.2~0.8 | 0.2~0.8 |

| Tensile strength | ISO527-1 | MPa | 30 | 20 | 27 | 18 | 27 |

| Elongation | % | 15 | 250 | 200 | 250 | 40 | |

| Flexural strength | ISO178 | MPa | 50 | 24 | 37 | 21 | 34 |

| Flexural modulus | MPa | 1550 | 1400 | 1200 | 1100 | 1500 | |

| Flexural modulus | ISO2039-2 | R Scale | 88 | <10 | 55 | <10 | <10 |

| Durometer hardness |

ISO868 | D Scale | 75 | 62 | 71 | 55 | 68 |

| Charpy impact strength unnotched |

ISO179 | KJ/㎡ | 16 | NB | 100 | NB | NB |

| Charpy impact strength V-notched |

KJ/㎡ | 1.3 | P | 2 | P | 2 | |

| heat distortion temp |

ISO75-1 | ℃ | 63 | 65 | 57 | 60 | 62 |

| Vicat softening point |

ISO306 | ℃ | 91 | 83 | 82 | 72 | 81 |

| Total light transmission |

ISO13468 | % | 90 | 89 | 90 | 89 | 88 |

| Haze | ISO14782 | % | 0.5 | 1.2 | 0.5 | 2.0 | 1.2 |

| Typical applications | Cosmetics cap, Food containers |

Cosmetics cap, Food containers |

Blister, packaging Toys |

cups for cold bervarages, cold ice packaging |

Drink caps , cold ice packaging |

||

GRADE LINE UP

| Property | Test Method | Units | Sheet | |||

|---|---|---|---|---|---|---|

| 800S | 851 | 864 | 860S | |||

| Density | ISO1183 | Kg/㎥ | 1.02×10³ | 1.03×10³ | 1.02×10³ | 1.02×10³ |

| Water absorption | ISO62 | % | <0.1 | <0.1 | <0.1 | <0.1 |

| MFR(200℃) | ISO1133 | g./10min | 6 | 3.5 | 6 | 10 |

| Mold shrinkage | - | % | 0.2~0.8 | 0.2~0.8 | 0.2~0.8 | 0.2~0.8 |

| Tensile strength | ISO527-1 | MPa | 41 | 57 | 33 | 34 |

| Elongation | % | 12 | 4 | 45 | 7 | |

| Flexural strength | ISO178 | MPa | 54 | 90 | 45 | 60 |

| Flexural modulus | MPa | 2250 | 3150 | 1590 | 2090 | |

| Flexural modulus | ISO2039-2 | R Scale | 78 | 114 | 61 | 96 |

| Durometer hardness | ISO868 | D Scale | 75 | 81 | 71 | 77 |

| Charpy impact strength unnotched |

ISO179 | KJ/㎡ | 23 | 30 | 21 | 18 |

| Charpy impact strength V-notched |

KJ/㎡ | 1.1 | 2.4 | 1.2 | 1.3 | |

| heat distortion temp | ISO75-1 | ℃ | 69 | 58 | 54 | 54 |

| Vicat softening point | ISO306 | ℃ | 96 | 69 | 72 | 74 |

| Total light transmission | ISO13468 | % | 90 | 90 | 83 | 80 |

| Haze | ISO14782 | % | 3.0 | 2.0 | 5.0 | 3.0 |

| Typical applications | Cosmetics cap, Food containers |

Garment Hangers | Shrink film | Shrink film | ||