PP MOLDING COMPOUND (Panasonic)

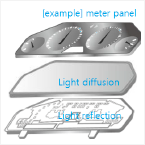

Vehicle cluster (instrument panel) diffusion / PP molding compound for reflector

With combining the diffusion and the reflection, Improve the luminescent performance, durability and weight reduction

[ Diffusion ]

- The same light diffusion level as PC

- 30% weight saving than PC

- Cost cutting (35%)

- mprove the chemical resistance

Diffusion Grade

| Test item | Unit | MBG105H | |

|---|---|---|---|

| Grade | - | Standard Grade | High functional Grade |

| Haze | - | 91.6 | 91.7 |

| All light ray transmission | % | 66.4 | 58.3 |

| Diffuse ray transmission | % | 60.8 | 53.4 |

| Parallel transmission | % | 5.6 | 4.9 |

| Density | g/㎤ | 0.94 | 0.96 |

| Heat deflection temperature(4.6kgf) | ℃ | 122 | 125 |

| Heat deflection temperature (18.6kgf) | ℃ | 70 | 75 |

[ Reflection ]

- The same light reflection level as PC

- 20% weight saving than PC

- Cost cutting (25%)

- Improvement the chemical resistance

Reflection Grade

| Test item | Unit | MBG130H11 | |

|---|---|---|---|

| Color | L | - | 96.6 |

| A | - | -0.51 | |

| B | - | 1.13 | |

| Reflection rate | 500nm | % | 95 |

| 600nm | % | 96 | |

| Density | g/㎤ | 127 | |

| Heat deflection temperature (4.6kgf) | ℃ | 135 | |

| Heat deflection temperature (18.6kgf) | ℃ | 90 | |

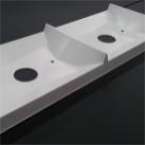

PP molding compound for sheet・anomaly extrusion

MBG120H11P is for the sheet which is from 500μm thick suitable for the 2nd fabricating such as a deep drawing vacuum molding.

Material features

- High reflectance(reflectance97%)

- Heat resistance and color fastness.

- Chemical resistance・copper inhibition

- Variant form extrusion molding after T die extrusion molding.

- T die sheet is suitable for deep drawing vacuum molding for large parts.

- Hinge property

Applications

Lighting apparatus

Back sheet of light guide plate

Plant factory reflector

Screen

LED display

PP molding compound for a film

MBG130H11 is for 100~400μm film With small ultraviolet tarnish, achieve the long shelf-life

Features

- High reflectance(reflectance 98%)

- Heat resistance and color fastness

- Chemical resistance・copper inhibition

- Color difference is under ΔE1 in the test of 10years worth test of outside

Workability

- Good moldability with small retension(meyani) on T die extrusion

- No need a post-process such as ultraviolet paint

Applications

Lighting apparatus

Back sheet of light guide plate

Plant factory reflector

Screen