PANLITE SHEET & FILM

Teijin Panlite Sheet Line up for Automotive

| Item | Test Condition | Unit | PC-1151 2.0mmt |

PC-D101 2.0mm |

PC-MA51 2.0mm |

PC-JA53 2.0mm |

|

|---|---|---|---|---|---|---|---|

| Density | JIS K7112 | (g/㎤) | 1.2 | 1.2 | 1.2 | 1.2 | |

| Optical characteristic |

Total transmittance | JIS K6735 | (%) | 89 | 91 | 91 | 91 |

| Haze | JIS K6735 | (%) | 0.2 | 0.2 | 0.2 | 0.2 | |

| Anti-shick property |

Punching workability |

120x180mm With panching |

(-) | o | o | o | O |

| Falling ball impact test |

45.5g 100cm | (-) | O(no crack) | O(no crack) | O(no crack) | O(no crack) | |

| Hardness | Pencil hardness | HIS K5600 | (-) | 2B | 2H | 4H | 2H |

| 2B | 2B | HB | B | ||||

| Taaber abrasion test |

JIS K6735 CS-10F TYPEIV 500g (100rotations) |

% | 35 | 30 | 5 | 30 | |

| 35 | 35 | 5 | 5 | ||||

Main Line up & Features

| Grade | PC-1151 | PC-D101 | PC-MA51 | PC-JA53 |

|---|---|---|---|---|

| Composition |  |

|

|

|

| Pencil hardness | 2B | 2H / 2B | 4H / HB | 2H / B |

| Characteristic | Normal grade Good workability |

High hardness Good workability |

Coating on both sides Pencil Hardness(4H) |

Coating on PC side (Scratch resistance) |

PC Film(Isotropic ) Line-up

| Melt | Cast (High MW) | Other material | ||||||

|---|---|---|---|---|---|---|---|---|

| Gen.PC D |

Gen.PC C110 |

Modified PC | ETFE | PI | PEN Q65 |

PET O5 |

||

| M5 | S5 | |||||||

| Thickness ㎛ | 50-100 | 50-120 | 50-120 | 80-100 | 50 | 100 | 100 | |

| Density | 1.20 | 1.20 | 1.20 | 1.20 | 1.73 | 1.43 | 1.36 | 1.40 |

| Reflective index | 1.58 | 1.58 | 1.62 | 1.62 | 1.40 | 1.75 | 1.75 | 1.66 |

| Tg ℃ | 145 | 155 | 215 | 225 | (150) | 360< | 155 | 110 |

| CTE ppm/℃ | 80 | 80 | 70 | 70 | 94 | 20 | 17 | 24 |

| Water absorption coefficient |

0.2 | 0.2 | 0.3 | 0.3 | 0.03 | 1.3 | 0.3 | 0.4 |

| Young'smodulus MPa | 2600 | 2200 | 2500 | 2500 | 800 | 3600 | 6000 | 5500 |

| Tensile Strength MPa | 56 | 65 | 100 | 100 | 70 | 280 | 280 | 230 |

| Tensile Elongation % | 5 | 130 | 10 | 9 | 450 | 90 | 90 | 120 |

| Thermal shrinkage % | <0.1 @140℃ |

<0.1 @150℃ |

<0.1 @180℃ |

<0.1 @200℃ |

~0.1 @150 | ~0.4 @150 | ~1.0 @150 | |

| Haze % | 0.1 | 0.1 | 0.2 | 0.2 | 7 | 0.5 | 0.5 | |

| Total transmittance % | 90 | 90 | 89 | 89 | 95 | 87 | 88 | |

PC Retardation Film Line-up

| Melt | Cast (High MW) | Other material | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| General PC | Modified PC | General PC | Modified PC | COP ARTON |

COP ZEONOR |

|||||||

| GT | GS | GR | RM | FM | TT | T | WR-M | WR-S | WR-W | |||

| Thickness ㎛ | 30~40 | 60 | 70 | 53 | 57 | 40~45 | 60~70 | 75~ 100 |

50 | 75 | 100 | 100 |

| Density | 1.20 | 1.20 | 1.10 | 1.18 | 1.18 | 1.20 | 1.20 | 1.20 | 1.20 | 1.20 | 1.08 | 1.01 |

| Reflective index | 1.58 | 1.58 | 1.58 | 1.54 | 1.54 | 1.58 | 1.58 | 1.62 | 1.62 | 1.62 | 1.51 | 1.53 |

| Tg ℃ | 145 | 145 | 145 | 138 | 1.38 | 155 | 155 | 215 | 225 | 227 | 171 | 138 |

| CTE ppm/℃ | 80 | 80 | 80 | 75 | 75 | 80 | 80 | 77 | 77 | 77 | 70 | 60 |

| Retardation nm | 120~ 430 |

120~ 140 |

120~ 580 |

143~ 147 |

143~ 147 |

120~ 430 |

120~ 580 |

138 | 148 | 142 | ||

| N2 Coefficient | 1.0 | 1.0 | 1.0 | 1.2 | 1.2 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | ||

| Wavelength Dispersion |

1.10 0.96 |

1.10 0.96 |

1.10 0.96 |

0.89 1.04 |

0.84 1.06 |

1.10 0.96 |

1.10 0.96 |

1.03 0.98 |

0.91 1.03 |

0.83 1.05 |

1.01 1.00 |

1.01 1.00 |

| Photo elasticity | 80 | 80 | 80 | 15 | 18 | 80 | 80 | 45 | 40 | 35 | 4 | 6 |

| Haze % | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.2 | 0.2 | 0.2 | 0.3 | 0.1 |

| Total transmittance % |

90 | 90 | 90 | 91 | 91 | 90 | 90 | 89 | 89 | 89 | 92 | 92 |

Wide-band retardation with single film

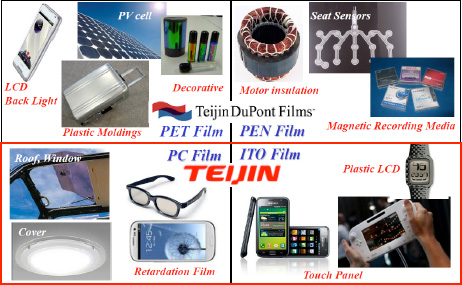

Application Examples of Teijin Film